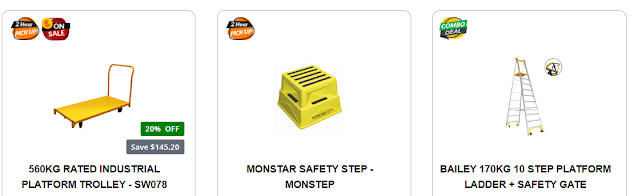

Key Considerations When Purchasing Material Handling Equipment

In the complex realm of modern

business operations, the selection of material handling equipment is a pivotal

decision that can significantly impact efficiency, productivity, and

bottom-line results. With a multitude of options available, making an informed

choice requires a comprehensive understanding of various factors. This article

serves as your compass, guiding you through the crucial considerations to keep

in mind when purchasing material handling equipment provided by equip2.com.au.

1.

Operational Needs and Scope: Begin by assessing your

specific operational requirements. Consider factors such as the volume of

materials to be handled, the size and weight of the items, and the frequency of

material movement. A clear understanding of your scope sets the stage for

choosing the right equipment.

2. Type of

Material: Different materials have distinct handling needs. Whether

it's palletized goods, liquids, bulk materials, or irregularly shaped items,

ensure the equipment is designed to accommodate the unique characteristics of

your materials.

3. Space and

Facility Layout: Evaluate your warehouse or facility layout. Measure

available space, aisle widths, and ceiling heights. The equipment should

seamlessly integrate into your existing setup without causing congestion or hindering operations.

4. Equipment

Compatibility: Consider the compatibility of the equipment with your

existing processes and infrastructure. Will it work well with your existing

forklifts, conveyors, or other equipment? Seamless integration is crucial to

ensure a smooth flow of operations.

5. Safety

Features: Ensure the equipment is equipped with necessary safety features

such as guards, sensors, emergency stop buttons, and visibility enhancements to

protect both employees and materials.

6. Maintenance

and Servicing: Evaluate the maintenance requirements of the equipment. Does

the manufacturer offer reliable service and support? Ease of maintenance and

availability of replacement parts are essential for minimizing downtime.

7. Cost

Considerations: Beyond the initial purchase price, factor in long-term

costs. Consider operational costs such as energy consumption, maintenance,

repairs, and potential downtime. A thorough cost analysis helps determine the

true value of the investment.

8. Training

and Operator Skill: Ensure that your team is adequately trained to operate the

equipment safely and efficiently. Factor in the training time and costs

required to maximize the equipment's potential.

9. Future

Scalability: Anticipate future growth and changing needs. Opt for

equipment that can adapt to evolving requirements and accommodate increased

demand.

10. Reviews

and Recommendations: Research user reviews and seek recommendations from industry

peers who have experience with the equipment you're considering. Their insights

can provide valuable perspectives.

11. Warranty

and Support: Investigate the warranty terms and after-sales support

provided by the manufacturer. A reliable warranty and responsive customer

support can provide peace of mind.

Conclusion

The purchase of materialhandling equipment is a strategic investment that shapes the efficiency and

effectiveness of your operations. By carefully considering operational needs,

safety features, compatibility, and long-term costs, you can make an informed

decision that aligns with your business goals. As you navigate the complex

landscape of material handling equipment options, remember that a well-chosen

investment today can lead to increased productivity, streamlined processes, and

a competitive edge in the ever-evolving business landscape.

Comments

Post a Comment