Maximizing Efficiency and Safety in Material Handling: A Comprehensive Guide

Efficient

material handling is the backbone of any successful operation, ensuring that

goods move seamlessly through various stages of production and distribution.

Simultaneously, maintaining a safe working environment is paramount to protect

both employees and assets. To strike the right balance between efficiency and

safety, organizations must leverage advanced material handling equipment from equip2go.com.au and implement

robust protocols. In this blog post, we'll explore key strategies to enhance

efficiency and safety in material handling operations.

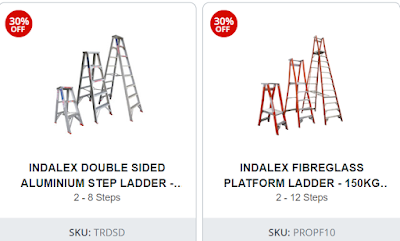

Invest in Modern Material Handling

Equipment:

To

boost efficiency, it's crucial to invest in state-of-the-art material handling

equipment. Automated guided vehicles (AGVs), conveyor systems, and robotic arms

are examples of cutting-edge technology that can streamline processes, reduce

human error, and enhance overall productivity. Additionally, modern equipment

often comes with built-in safety features, contributing to a safer work

environment.

Employee Training and Education:

Equip

your workforce with the skills and knowledge required to operate material

handling equipment safely and efficiently. Conduct regular training sessions to

update employees on the latest industry standards, safety protocols, and equipment

functionalities. Well-trained operators are more likely to optimize the use of

material handling tools, leading to improved efficiency and reduced incidents.

Implement Strict Safety Protocols:

Develop

and enforce comprehensive safety protocols specific to material handling

operations. Clearly communicate these guidelines to all personnel involved in

the process. This should include proper lifting techniques, equipment operation

procedures, and emergency response plans. Regular safety audits can help identify

and rectify potential hazards before they escalate.

Use Ergonomic Design Principles:

Consider

the ergonomic design of both workstations and material handling equipment.

Ergonomically designed equipment reduces the physical strain on workers, minimizing

the risk of injuries and fatigue. For example, adjustable-height workstations

and ergonomic handles on lifting equipment contribute to a safer and more

efficient work environment.

Implement Real-time Monitoring Systems:

Incorporate

real-time monitoring systems to track the performance and condition of material

handling equipment. This technology allows for predictive maintenance,

preventing unexpected breakdowns and optimizing equipment uptime. Monitoring

systems also contribute to safety by providing insights into operator behavior

and identifying potential safety risks.

Optimize Layout and Workflow:

A

well-designed layout can significantly impact material handling efficiency.

Analyze and optimize the flow of materials through the facility, minimizing unnecessary

movements and delays. Implementing a logical and streamlined workflow reduces

the chances of accidents and enhances overall productivity.

Utilize RFID and Barcode Technology:

RFID

(Radio-Frequency Identification) and barcode technology can streamline material

tracking and reduce errors. By accurately identifying and monitoring the

movement of materials, organizations can enhance inventory management, prevent

losses, and improve overall efficiency. This technology also contributes to

safety by ensuring the correct handling of products.

Encourage a Safety Culture:

Foster

a safety-first culture within the organization. Encourage employees to report

safety concerns and incidents promptly. Recognize and reward safe behavior to

create a positive reinforcement loop. When employees prioritize safety, it

naturally contributes to increased efficiency as they become more conscientious

about their actions.

Regular Maintenance and Inspections:

Schedule

routine maintenance checks for all material handling equipment. Regular

inspections help identify potential issues before they escalate, preventing

costly downtime and ensuring the safety of operators. Establish a comprehensive

maintenance schedule that includes both preventive and predictive maintenance

measures.

Continuous Improvement:

Implement

a continuous improvement mindset within the organization. Regularly assess

material handling processes, gather feedback from employees, and seek

opportunities for enhancement. Embrace new technologies and methodologies to

stay at the forefront of industry advancements, ensuring sustained efficiency

and safety improvements.

Conclusion:

Efficiency

and safety are intertwined aspects of successful material handling operations.

By investing in modern equipment, prioritizing employee training, and

implementing stringent safety protocols, organizations can create a workplace

that not only maximizes productivity but also safeguards the well-being of

their workforce. Adopting a holistic approach that combines advanced

technology, employee empowerment, and a commitment to continuous improvement

will position businesses for long-term success in the dynamic world of material

handling.

Comments

Post a Comment