Material Handling Solutions for Heavy Machinery and Components

In industries that deal with large and heavy objects, such as

manufacturing, construction, and logistics, efficient material handling is

crucial for productivity and safety. Moving hefty machinery and components

demands specialized equipment and careful planning to ensure smooth operations.

Explore the realm of material handling solutions tailored by equip2go.com.au for heavy machinery

and components, exploring innovative technologies and best practices aimed at

enhancing efficiency and safety.

Understanding the

Challenge

Handling heavy machinery and components presents unique challenges due to

their weight, size, and often irregular shapes. Traditional methods relying

solely on manual labor are not only inefficient but also pose significant

safety risks to workers. Accidents such as strains, sprains, and crush injuries

are common when attempting to lift or move heavy objects manually. Moreover,

improper handling can lead to damage to the equipment or surrounding

infrastructure, resulting in costly repairs and downtime.

Specialized

Equipment for Heavy Material Handling

Forklifts and Crane Systems: Forklifts equipped with high-capacity lifting

capabilities are indispensable in industrial settings for moving heavy

machinery and components within a facility. Similarly, crane systems offer

versatility in lifting and transporting bulky objects, especially in

construction sites where large structures or machinery need to be erected or

relocated.

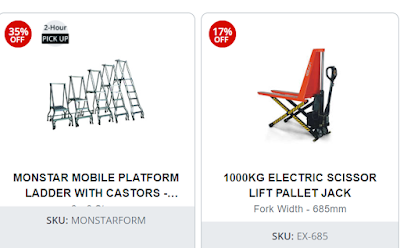

Hydraulic Lifts and Jacks: Hydraulic lift tables and jacks provide

controlled lifting and lowering of heavy loads, allowing for precise

positioning during assembly or maintenance tasks. These tools are particularly

useful in workshops and maintenance bays where space may be limited, and

maneuverability is essential.

Conveyor Systems: Conveyor belts and rollers offer a continuous flow of

materials, streamlining the movement of heavy components along assembly lines

or within warehouses. These systems are customizable to accommodate various

shapes and sizes, reducing manual handling and minimizing the risk of damage or

injury.

Pallet Jacks and Skid Steers: Pallet jacks and skid steers are essential

tools for transporting palletized loads of heavy machinery or components within

a facility. Their compact size and maneuverability make them ideal for

navigating tight spaces while ensuring efficient material flow.

Innovative

Technologies Driving Efficiency

Internet of Things (IoT) Integration: IoT-enabled sensors and monitoring

devices provide real-time insights into material handling processes, allowing

for proactive maintenance and optimization of equipment usage. By harnessing

data analytics, companies can identify inefficiencies, minimize downtime, and

enhance overall productivity.

Predictive Maintenance Solutions: Leveraging predictive maintenance

software, companies can anticipate equipment failures and schedule maintenance

activities proactively, thereby minimizing disruptions to material handling

operations. By addressing issues before they escalate, organizations can

optimize uptime and extend the lifespan of their assets.

Best Practices

for Safe Material Handling

Employee Training and Certification: Proper training and certification

programs are essential for personnel involved in material handling tasks,

ensuring they have the knowledge and skills to operate equipment safely and

efficiently. Ongoing training sessions should emphasize best practices, risk

awareness, and emergency procedures to mitigate workplace accidents.

Load Assessment and Planning: Before lifting or moving heavy objects,

conducting a thorough assessment of the load's weight, dimensions, and center

of gravity is critical for selecting the appropriate handling equipment and

techniques. Proper planning minimizes the risk of accidents and ensures smooth

execution of material handling tasks.

Use of Personal Protective Equipment (PPE): Workers engaged in material

handling activities should wear appropriate PPE, including safety gloves,

steel-toed boots, and hard hats, to protect against potential hazards such as

falling objects or crushing injuries. Adhering to PPE guidelines significantly

reduces the risk of workplace accidents and enhances employee safety.

Regular Equipment Inspection and Maintenance: Routine inspection and

maintenance of material handling equipment are vital for identifying potential

issues and ensuring optimal performance. Any signs of wear, damage, or

malfunction should be addressed promptly to prevent accidents and maintain operational

efficiency.

Conclusion

Effective material handling

solutions are indispensable for industries dealing with heavy machinery and

components, enabling organizations to optimize productivity, minimize risks,

and ensure the safety of their workforce. By leveraging specialized equipment,

innovative technologies, and best practices, companies can streamline material

flow, enhance operational efficiency, and maintain a competitive edge in

today's dynamic business landscape. Prioritizing safety, training, and continuous

improvement fosters a culture of excellence where employees can thrive while

achieving organizational objectives.

Comments

Post a Comment