3 Budget-Friendly Solutions to Automate Your Warehouse and Boost Efficiency

The allure of a fully automated warehouse is

undeniable. Increased efficiency, reduced errors, and happier employees all

sound fantastic. But the hefty price tag often associated with automation can

leave smaller warehouses or those just starting out feeling discouraged. Fear

not! Warehouse automation doesn't have to break the bank.

Here are 3 inexpensive system solutions from equip2go.com.au to get you started

on your automation journey:

1. Unleash the Power of

Software: Warehouse Management Systems (WMS)

Think of a WMS as the brain of your warehouse. It

centralizes all your inventory data, order fulfillment processes, and picking

operations. While full-featured WMS

solutions can be expensive, there are plenty of affordable cloud-based options

available. These can streamline tasks

like:

·

Inventory Management: Say goodbye to

manual spreadsheets and hello to real-time inventory tracking. A WMS keeps you

updated on stock levels, minimizes stockouts, and optimizes product placement

for efficient picking.

·

Order Fulfillment Automation: No

more scrambling to fulfill orders. A WMS automates order picking by generating

pick lists, directing pickers to the correct locations, and even suggesting the

most efficient picking routes. This translates to faster fulfillment times and

happier customers.

·

Data-Driven Decision Making: A WMS

collects valuable data on warehouse operations, allowing you to identify

bottlenecks, analyze trends, and make informed decisions about future

automation investments.

·

Cost-Effectiveness: Cloud-based WMS

solutions come with affordable subscription plans, eliminating the upfront

costs of traditional software licenses. Plus, the efficiency gains translate to

real cost savings in labor and reduced errors.

Pro Tip: Many WMS providers offer free trials or

scaled-down versions for smaller warehouses. Utilize these to test the software

and see how it integrates with your existing workflows before committing.

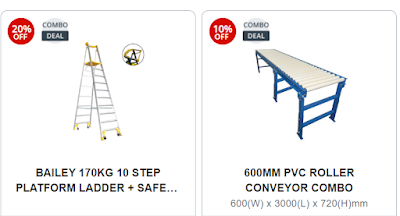

2. Let it Flow: Motorized Roller Conveyors

This may seem like a simple solution, but motorized roller

conveyors can significantly improve warehouse throughput. These conveyors move boxes, totes, and

pallets automatically, freeing up your workforce to focus on higher-value tasks

like picking and packing.

·

Reduced Labor Costs: Automated

movement of goods minimizes the need for manual pushing and pulling, saving

labor hours and associated costs.

·

Improved Efficiency: Conveyors

streamline the flow of goods, reducing travel time for workers and ensuring a

smoother picking and packing process.

·

Ergonomic Benefits: By eliminating

manual movement of heavy items, conveyors reduce the risk of workplace

injuries.

·

Cost-Effectiveness: Motorized roller conveyors offer a relatively

low upfront cost and require minimal maintenance. They can be

easily scaled by adding additional sections as your needs

grow.

Pro Tip: Consider modular conveyor systems that can be easily reconfigured as your warehouse

layout changes.

3. Embrace the Put-and-Take

Power: Pick-to-Light Systems

Imagine a system that guides pickers to the exact

location of each item they need.

Pick-to-light systems do exactly that.

Shelving units are equipped with lights that illuminate when an item

needs to be picked for an order. This

eliminates time wasted searching for items and minimizes picking errors.

·

Increased Picking Accuracy:

Pick-to-light systems reduce errors dramatically by visually directing pickers

to the correct location.

·

Improved Picking Speed: By

eliminating wasted time searching for items, pickers can complete orders much

faster.

·

Reduced Training Time: The

simplicity of pick-to-light systems minimizes training time for new staff.

·

Cost-Effectiveness: While not the cheapest solution,

pick-to-light systems offer a great return on investment by increasing picking

accuracy and speed. Many providers offer

modular systems that can be scaled tofit your specific needs and budget.

Pro Tip:

Integrate your pick-to-light system with your WMS for a seamless picking

experience. The WMS can automatically send picking instructions to the light system,

further enhancing efficiency.

Forget the giant industrial robots you see in

movies. AMRs are a smaller, more

affordable breed of robots perfectly suited for repetitive tasks in

warehouses. These autonomous vehicles

can navigate your warehouse using sensors and avoid obstacles.

Comments

Post a Comment